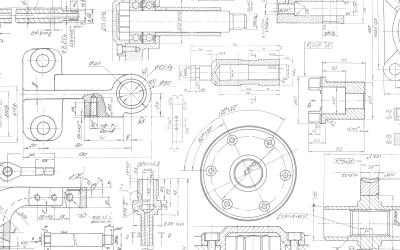

Engineering & Design

Turcont Engineering & Manufacturing is one-stop source in machining industry from concept and design works to final delivery services of goods to the clients locally and internationally.

In this phase, you will have opportunity to involve in development process in order to produce a prototype that meets your expectations in terms of reliability and quality.

Our Engineering & Design Division executes its mission by utilizing the latest technology in CAD / CAM software, SOLIDWORKS.

The Division supports the manufacturing with 2D CAD, 3D CAD, and CAM modules.

Turcont engineers provide services for the data received from the customers as technical drawings, samples, or electronic files in different formats such as IGES, .STEP, DXF, DWG, .X_T, .IGS, .ASM

These services include;

- Solid modelling,

- Creating casting molds,

- Producing forging dies,

- Creating machining fixtures

MITUTOYO CRYSTA – APEX S 9106

Coordinate Measuring Machine

With the CMM machine, we can produce solid models by applying reverse engineering or by modifying and creating new shapes on existing samples.

Range: 900 mm x 1.000 mm x 600 mm

- Air supply: Pressure = 0,4 MPa

- Loading Weight: 1.200 kg

- Mass Weight: 2.231 kg

- Max drive speed: 519 mm/s (3-axis)

- E0,MPE:

- with SP25M: (1,7+4L/1000) µm;

- with TP200: (1,9+4L/1000) µm;

- with TP20: (2,2+4L/1000) µm;

- L = measured length [mm]

3D Acceleration: 2.309 mm/s2

Temperature compensation from 16° to 26°C, including the workpiece (2 contact sensors)

We believe that we are perfect fit for assisting our customers with the design of new components to optimize manufacturing without compromising quality and functionality. We owe this skill to our expertise and experience in different types of casting and machining we have been working on since 1986.

Turcont Engineering Divison is also happy to serve our customers with below services…

Engineering Support

3D CAD Modeling

Mechanical Design

3D Scanning

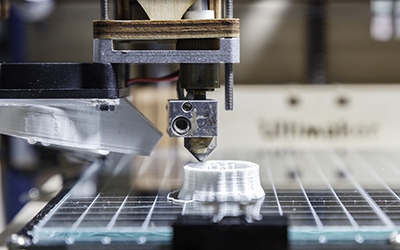

3D Printing

3D Rendering

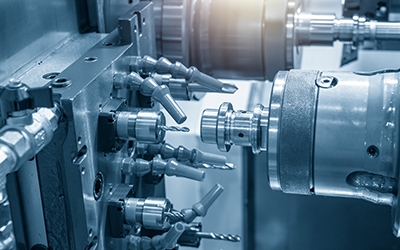

CNC Machining